ISHITVA® Food Sorter

IshitvaAI sees what the human eye and conventional sorters miss.

Engineered for real-world variability, ISHITVA® combines ultra-HD color vision and AI-driven defect detection for superior quality assurance across the full spectrum of India’s food categories.

With ISHITVA® Food Sorter, that future is here.

Pulses

Nuts

Dehydrated Onion/Garlic

Species

Application-Specific Sorting – Problems We Solve

Dry Fruits: Cashews, Almonds, Pistachios, Raisins

Impurities:

- Color variance due to roasting or drying

- Burnt tips, insect bites, and mold spots

- Broken or undersized kernels reducing grade

- Foreign matter (shells, husk, stones, plastic)

Output You Can Expect:

- Ultra-HD Color Vision detects surface burns, mold discoloration, and color inconsistencies

- AI filters out undersized kernels and broken halves with precision

- Foreign object detection isolates shell pieces, stones, plastics, even if transparent

Value Delivered:

- Export-grade consistency

- Maximize yield from every batch

- Eliminate returns from quality rejections

Dehydrated Foods: Onion, Garlic, Vegetables & Flakes

Impurities:

- Unwanted color variations

- Burnt pieces, impurities & foreign particles

- Inconsistent sizes or textures

Output You Can Expect:

- Visual layer AI differentiates between burnt vs. properly dried

- Detects dark micro-flakes, fungal infection marks, or color phase variance

- Separate skin particles that have off pattern or color using surface pattern recognition with AI

Value Delivered:

- Uniform appearance for rehydrated use

- Accurate sorting for foodservice and export buyers

- Reduced manual labor in quality control

Spices & Herbs: Chilli, Turmeric, Cumin, Coriander, Leafy Herbs

Impurities:

- High variability in color and shape across harvests

- Fungal spots, shriveled pods, or moisture-induced blackening

- Plastic threads, twigs, and husk contaminants

Output You Can Expect:

- AI identifies discoloration, moisture-darkened areas, and fungal marks

- Detects non-uniform size in seeds (e.g. cumin or coriander)

- Removes foreign polymers, stones, and even transparent plastic

Value Delivered:

- Precise grading for high-value spices

- Extended shelf life through defect elimination

- Higher export premiums

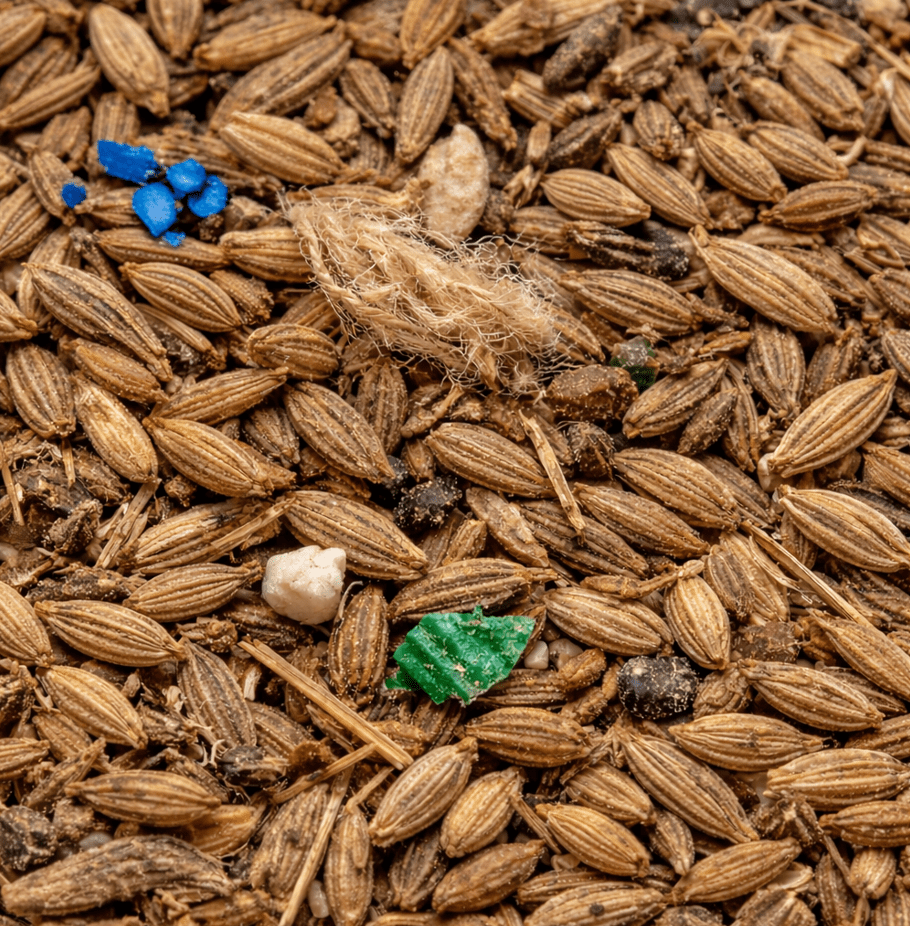

Seeds & Pulses: Sesame, Mustard, Chana, Dals

Impurities:

- Shriveled seeds, splits, and inconsistent color grades

- Stones, weed seeds, dust clumps

- Burnt or immature seeds affecting oil extraction or taste

Output You Can Expect:

- Differentiates shriveled or malformed pulses via size/shape filters

- Color uniformity detection ensures standardized grading

- Eliminates burnt particles, metal specks, and weed seeds

Value Delivered:

- Cleaner product for milling, packaging, and export

- Reduced sorting time

- Higher oil yield and better taste profile

Industries We Serve

Food Processing & Ingredients Companies

Spice & Seasoning Manufactures

Exporters of Food Ingredients

Bulk Packaging & Distribution Centers

Quality-Driven Retail Ingredient Suppliers

Benefits You Can Count On

- Superior Quality & Consistency Ensure uniform color, size, and grade

- Reduced Contamination Risks Detect and remove foreign and defective particles

- Higher Throughput, Lower Labor Automated sorting boosts operational efficiency

- Improved Market Value Premium product quality helps secure better pricing

- Global Food Safety Compliance Aligns with international food quality expectations