ISHITVA® Flake Sorter

In plastic recycling, purity is profit. Even a few contaminated flakes can reduce batch value, impact quality, and increase rejections. That’s why visual inspection or random sampling is no longer enough.

Sort by Polymer. Sort by Color.

NIR + Color/UV

Ishitva’s Flake Sorter

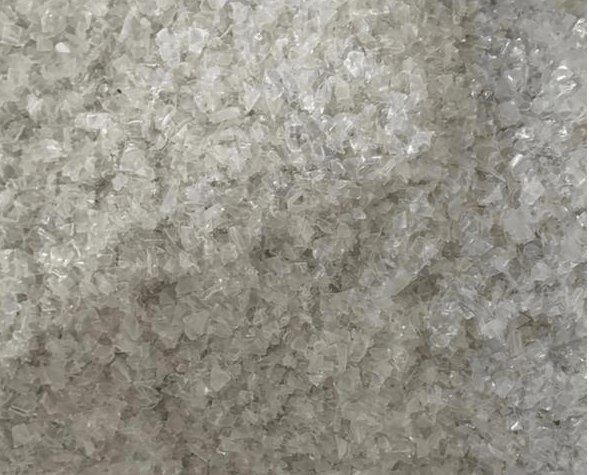

The Ishitva® Flake Sorter features a powerful combined sensor suite that integrates NIR, UV, color imaging, and AI for the precise detection and separation of foreign polymers and colors, even in fine flakes from 2mm to 20 mm.

Enables accurate material identification and ensures sorting performance that consistently achieves targeted PPM purity levels aligned with global standards. Requires minimal setup and offers seamless integration into existing lines with flexible configuration options for diverse polymer applications.

Why Ishitva’s Flake Sorter?

- Detects and ejects foreign polymers like HDPE, PP, BOPP labels, ABS, and degraded PET that manual or visual checks often miss.

- Enables recyclers to consistently reach <30 PPM contamination, essential for food-grade and bottle-to-bottle applications.

- Ensures uniform flake quality across batches, reducing rejections, debit notes, and buyer disputes.

- Accurately separates off-color and degraded flakes, increasing resale value and buyer confidence.

- Prevents foreign polymers from entering extrusion and filtration systems, reducing breakdowns and maintenance costs.

Key Capabilities

For PET Flakes

- Detects and separates unwanted polymers (HDPE, PP, PVC, PC, etc.)

- Identify and eject flakes with unwanted colors (Green, Brown, Black, Red, Orange, Yellow, degraded PET)

- Detects and separates metal fines coming from caps, closures, or neck rings

- Detects and separates BOPP PVC flakes coming from labels and sleeves

- Maintain <30 PPM contamination levels

- Enable high-purity bottle-to-bottle or food-grade rPET output

For HDPE & PP Regrinds

- Separate by polymer type, color, and even as per your MFI requirements.

- Detects and separates various polymer types, including PVC, PC, HIPS, ABS, and more.

- Identify and separates label residues, films, or colored contaminants

- Ensure consistent material quality for high-value upstream applications like caps, closures, pipes, and containers.

Feature and Specifications

Sorting Accuracy

Up to 99.8% (polymer-based)

Data Reporting

Batch-wise purity report (in PPM)

Detection Type

NIR + Color/UV

Integration

Conveyor or standalone modular setup Chutes 5

Supported Polymers

PET, HDPE, PP, PVC, PC, PS, ABS, etc

Send in your sample. Tell us what you want to sort

Why Choose Ishitva?

Ishitva Robotic Systems leads India’s automation wave in waste sorting and material recovery. We combine AI, vision, and deep material intelligence to help recyclers move from manual decisions to data-backed precision.

With the Flake Sorter, we go beyond sorting—we enable recyclers to deliver guaranteed purity, traceability, and value that global brands demand.

Your Path to Intelligent Sorting

Consultation

Evaluate your input material and purity goals

Training & Support

Equip your team with confidence to run autonomous analysis

Customization

Configure the Flake Sorter to your unique needs

Continuous Updates

Stay ahead with AI-driven model refinements

Integration

Empower your team with operational expertise