Ishitva® Flake Analyzer

Analyze, Validate & Improve Your Flake Streams

Beyond what humans or traditional tools can detect, giving recyclers clarity, precision, and confidence in every load they process.

What is Ishitva’s Flake Analyzer?

In recycling, even the smallest impurity can change everything. A batch of flakes that looks clean to the eye may still carry hidden contaminants— foreign polymers, labels, or off-colors—that affect quality, safety, and ultimately the price you get from buyers.

The Flake Analyzer by ISHITVA® is designed to solve this challenge. It’s an advanced material analysis system powered by AI, machine learning, and hyperspectral vision. In simple terms, it can “see” beyond what humans or traditional tools can detect, giving recyclers clarity, precision, and confidence in every load they process.

- For PET flakes, this means accurately identifying foreign polymers and color impurities—critical when you’re producing food-grade, bottle-to-bottler PET.

- For mixed plastics flakes, it means ensuring no foreign material sneaks in to compromise its end applications.

The system can analyze flakes and regrinds by polymer type, color, and volume—including dark and black objects that are usually the hardest to detect.

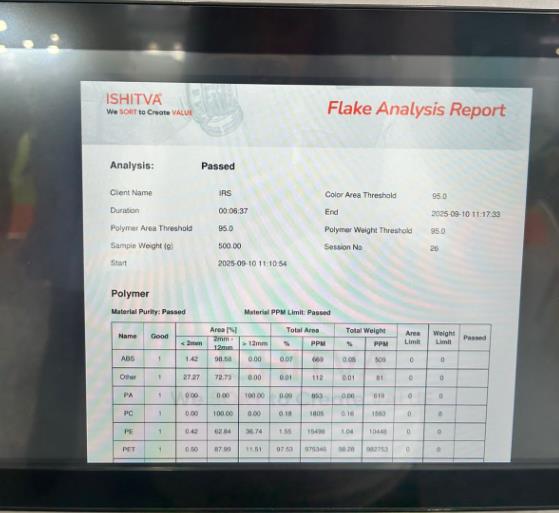

What makes it truly powerful is its ability to report contamination levels in PPM (parts per million). Why does that matter? Because in the industry, PPM defines value.

- Bottle-to-bottle applications demand less than 30 PPM.

- Bottle-to-fiber applications allow up to 100 PPM.

By knowing the exact PPM in real time, you can continuously refine your process, set the right price for your material, and build buyer trust with transparency.

With Ishitva’s Flake Analyzer, you don’t just check quality—you prove it.

Why Ishitva’s Flake Analyzer Matters?

Traditional checks of flake samples are slow, subjective, and inconsistent. The Flake Analyzer transforms this process with real-time, data-driven validation at the flake level.

With it, you can:

- Know the PPM level real time

- Eliminate manual guesswork

- Reduce rejections and debit notes

- Detect foreign polymers (unwanted polymers)

- Detect colour within polymers

- Continuously refine processes to maximize yield

- Spot wrong colors and impurities

- Meet buyer standards with confidence

- Maximize value and reduce waste

- Build trust with buyers through auditable quality data

With Ishitva’s Flake Analyzer you don’t just check your flakes, you prove their value.

Key Capabilities

For PET Flakes

- Detect foreign polymers, colors, and contaminants (Green, Brown, Black, Red, Orange, Yellow – degraded PET)

- Detect metal fines (from caps and neck collars)

- Detect HDPE/PP flakes comings from caps

- Detect BOPP flakes coming from labels

- Detect PVC material coming from labels

- Detect PC materials coming from flakes

- Generate reports with results measured in PPM

For Flakes (Mixed Plastics)

- Detect unwanted polymers, colors, and contaminants based on end applications

- Detect metals (from neck rings and collars)

- Identify PP and PET materials

- Detect PVC materials coming from labels

- Detect unwanted colours (all types)

- Detect foreign polymers(unwanted polymers)

- Generate reports with results measured in PPM

Feature and Specifications

Temperature range

+5°C - +40°C

Connectivity

Ethernet

Interface

Touch Screen

Compatible Sizes

1 mm - 30 mm

Who It’s For

Recyclers: Ensure outgoing material batches meet customer specs. Validate purity, eliminate rejections, and boost buyer trust.

Plastic Processors: Test incoming material before it enters your production line. Reduce risk, minimize downtime, and maintain production quality.

Quality Control Teams: Replace manual inspection with intelligent automation. Get reproducible results that drive smarter material decisions.

Brands: Support product authenticity, uphold compliance, and reinforce your brand’s values while contributing to sustainability efforts.

Real Impact – Measurable Results

- Higher margins per ton through purity validation

- Increased buyer trust with transparent, auditable data

- Compliance with EPR and FSSAI standards

Why Choose Ishitva?

Ishitva Robotic Systems is a pioneer in AI-driven recycling technologies, helping recyclers move beyond sorting to true process intelligence.

With the Flake Analyzer, we don’t just help you meet standards—we help you set them.

Your Path to Quality Assurance

Consultation

Assess your current flakes stream and goals

Training & Support

Equip your team with confidence to run autonomous analysis

Customization

Configure Analyzer to your specific needs

Continuous Updates

Stay ahead with upgrades and new detection capabilities

Integration

Seamlessly deploy into your quality check workflow