SANJIVANI® –

The World’s First Fully

Autonomous MRF

Turning Waste Into Opportunity –

Smarter, Faster, Cleaner

Imagine a world where waste sorting is no longer a bottleneck, where every recyclable is recovered with near-perfect precision, and where your facility runs seamlessly without manual sorting.

With SANJIVANI®, that future is here.

The Challenge We’re Solving

Recycling begins with one fundamental problem: waste arrives mixed, contaminated, and inconsistent. Unlike manufacturing, where materials follow a predictable pattern, waste is chaotic — different colors, shapes, polymers, brands, and even non-recyclables all end up in the same stream.

Across India and the world, recyclers face four core challenges

- Recovery of high value recyclables from the mixed stream

- Efficient recovery of plastics by polymer, color or grade like food-grade, cosmetics-grade

- Contamination that reduces the quality and market value of recyclates

- High operational costs that make scaling difficult

- Recovery of flexible plastics that are traditionally difficult to identify and separate.

How SANJIVANI solves these challenges?

SANJIVANI® transforms these challenges with an autonomous, AI-powered sorting system designed to identify, pick, and separate recyclables with precision.

-

Automate Sorting. Recover 80+ Categories of Recyclables

From PET, HDPE, and PP to multilayer materials, metals, paper, and even food grade plastics. SANJIVANI® can identify and separate and help you recover 80+ category of recyclabels -

98%+ Purity in Output

Whether you’re targeting food-grade PET flakes or high-quality HDPE, SANJIVANI® delivers output that meets or exceeds market and regulatory standards. -

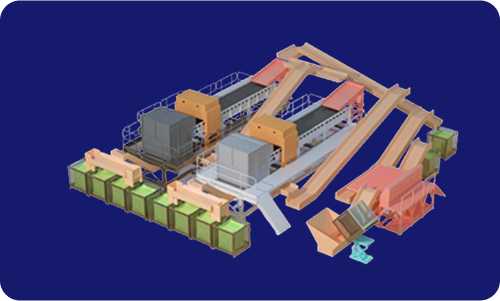

Full Plant Optimization

The system is designed to completely remove human pickers from the sorting line dramatically improving safety, efficiency, and consistency. -

Recycler Grade Seperation

Thanks to continuous machine learning, SANJIVANI® becomes more accurate over time adapting to changes in waste streams, packaging trends, and contamination challenges.

How SANJIVANI® Works

The process is intelligent, seamless, and fully automated:

Feed

Waste enters the facility and passes through our screening system to remove oversized materials and fine particles such as grits and small debris.

Decide

The AI makes an instant decision on where each item belongs, optimizing for purity, recovery rate, and value.

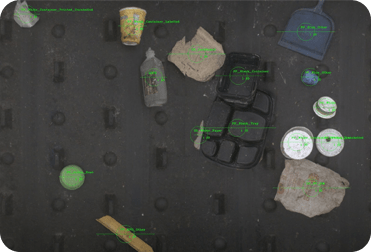

Identify

IshitvaAI identifies every item using advanced computer vision powered by deep learning — recognizing materials by color, polymer type, brand, and even food-grade classification.

Sort

Using high-speed precision ejection, SANJIVANI® separates items into clean, ready-to-recycle streams.

Segregated Recyclables

With SANJIVANI you get clean, category-wise segregated recyclables that are ready for direct recovery or sale

Key Features in Detail

IshitvaAI

- Identifies over 80+ types of materials in real time

- Can be tailored as per your output requirements

- Trained on millions of data

Full-Facility Automation

- Eliminates the need for multiple separate machines

- Integrates with conveyors, screens, shredders, and balers for a continuous operation

- Works 24/7 with minimal downtime

Data-Driven Insights

- Real-time analytics dashboard

- Detailed reporting for EPR submissions and regulatory audits

- Predictive maintenance alerts to prevent costly breakdowns

High Recovery Rates

- Up to 98% purity across multiple output streams

- Maximizes the value of recovered materials

- Reduces landfill dependency and disposal costs

Brand-Specific Sorting

- Enables closed-loop recycling for major FMCG brands

- Supports sustainability goals for producers and recyclers alike

Inquiry Now

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Who It’s For

- Municipal Material Recovery Facilities (MRFs) – Increase recovery rates and reduce contamination in city waste

- Private Recyclers – Maximize profitability with high-purity output

- Plastic Aggregators - who deal with large volumes of mixed waste and need fast, accurate, and profitable recovery of recyclables.

- EPR Stakeholders – Ensure traceability and accountability in recycling processes

Real Impact – Measurable Results

- 30–50% reduction in operational costs

- 20–40% increase in recovered material volume

- Significant improvement in worker safety and retention

- Consistent compliance with national and global recycling regulations

Why Choose Ishitva?

Ishitva Robotic Systems is a pioneer in AI-driven recycling technologies, helping recyclers move beyond sorting to true process intelligence.

With the Flake Analyzer, we don’t just help you meet standards—we help you set them.

Your Path to Autonomous Sorting

Consultation

We assess your current setup, waste stream, and goals

Customization

We design a SANJIVANI® configuration tailored to your needs

Installation

Our team handles seamless integration into your facility

Training & Handover

We empower your team to operate and maintain the system

Ongoing Support

We’re with you every step of the way for maintenance, updates, and upgrades

Join the Future of Recycling

With SANJIVANI®, you’re not just buying equipment—you’re investing in a smarter, more profitable, and sustainable future.

Reduce Costs | Increase Recovery | Boost Profitability Lead in Sustainability

Ready to Transform Your Facility?